Tous les produits

-

Pièces de moulage par injection de métal

-

Parties de moulage par injection de poudre

-

Pièces de métallurgie des poudres

-

Pièces métalliques sintrées

-

Parties d'usinage CNC

-

Parties d'usinage pour le tournage, le fraisage

-

AEG Partie Airsoft accessoires

-

Pièces de boîtes de vitesses pour pistolets airsoft

-

Outil porte-clés extérieur

-

Rameau à joints plats et lave-linge

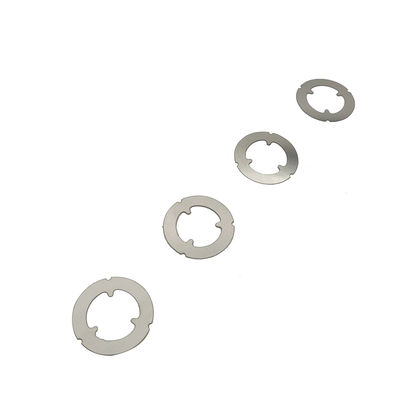

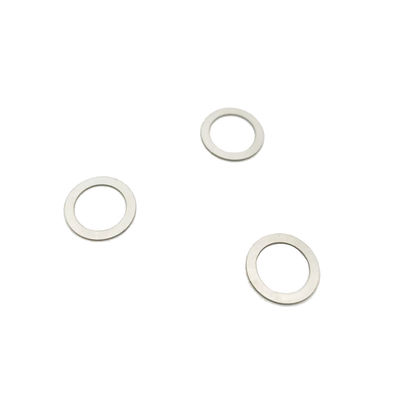

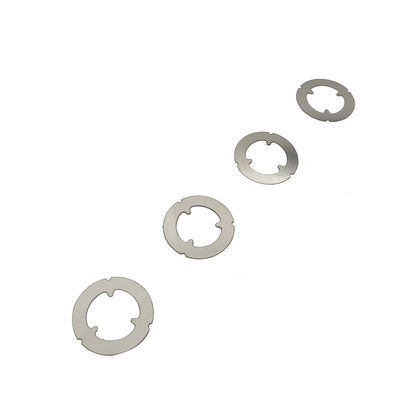

Customized Laser Cutting Stainless Steel Flat Washer Adjustment Shims with 2 Years Warranty and 0.02mm Tolerance

| Lieu d'origine | Guangdong, Chine |

|---|---|

| Nom de marque | MDM |

| Document | Brochure du produit PDF |

| Quantité de commande min | 1000 |

| Prix | $0.02-0.04 |

Contactez-moi pour des aperçus gratuits et des bons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Si vous avez n'importe quel souci, nous fournissons l'aide en ligne de 24 heures.

xDétails sur le produit

| Matériel | Acier inoxydable | Placage | Zinc |

|---|---|---|---|

| Poids | 0,01 kg | Traitement de surface | Anodisation |

| Tolérance | 0,02 mm | Méthode de traitement | Lathes à usinage CNC |

| Rugosité de surface | Ra est de 0,8-3.2 | Technique | Machinerie de tournage ou de fraisage CNC |

| Taille | Tailles personnalisées acceptables | Couleur | Couleurs personnalisées |

| Options matérielles | Aluminium 6061/7075, acier inoxydable 304/316/420/303, laiton, cuivre, titane, acier au carbone, aci | Options de préparation de surface | Le traitement de l'acier est effectué par des procédés tels que la fabrication d'aciers, de métaux o |

| Options de couleur | PVD noir/argent/jaune/doré, oxyde noir, zingage noir/argent/coloré | Quantité de commande min | 100 |

| Emballage | Poly sac + boîte intérieure + carton | ||

| Mettre en évidence | 2 Years Warranty Flat Washer,0.02mm Tolerance Adjustment Shim,100% QC Inspection Shim Washer |

||

Description de produit

Customized Laser Cutting Stainless Steel Flat Washer Adjustment Shims

Precision-engineered flat washer adjustment shims manufactured through advanced laser cutting technology for perfect fit and dimensional accuracy.

Product Specifications

| Material | Aluminum 6061/7075, stainless steel 304/316/420/303, Brass, copper, Titanium, Carbon steel, Mild steel, #45 steel, 4140, 4340, Kovar alloy |

| Surface treatment | Original or customized options including zinc plating, chrome plating, nickel plating, PVD coating, anodizing, polishing, sand blasting |

| Technics | CNC Turning/milling/machining/drilling/laser cutting/stamping/wire cutting |

| Sample | Sample costs refundable upon mass production confirmation |

| Surface Roughness | Ra 0.8-3.2 |

| Color | PVD black/silver/yellow/golden, black oxide, zinc plating black/silver/colorful etc. |

| Feature | Premium quality, 100% inspection before shipping, 2-year sales guarantee |

Company Profile

Dongguan Minda Metal Technology Co., Ltd., founded in 2015, specializes in precision manufacturing of CNC machining parts, MIM components, powder metallurgy parts, and aluminum/magnesium alloy die casting products. We also provide comprehensive mold design, development, and production services.

Our professional sales team maintains constant communication to understand customer requirements, which are promptly relayed to our technical staff. Our general manager provides rapid, accurate quotations tailored to your specific needs.

Throughout production, we implement rigorous quality control measures. Every product undergoes comprehensive inspection prior to shipment to ensure zero defects reach our customers.

With our expertise and your requirements, we provide complete hardware accessory solutions. Contact us anytime - we're available 24/7.

Packaging & Shipping

Frequently Asked Questions

Q1. What kind of documents do you need for a quotation?

A: We require PDF drawings or 3D files in STEP, IGS, or X_T format for accurate quotations.

Q2. Can you make the parts according to samples?

A: Yes, we can reverse engineer parts from physical samples. We'll create precise CAD models from your samples for production.

Q3. What kind of materials are used on your products normally?

A: We work with various materials including Aluminum, Steel, Brass, Stainless Steel, Bronze, and Titanium alloys.

Q4. Can you assemble the products?

A: Yes, we provide complete assembly services according to your specified requirements and assembly drawings.

produits recommandés