-

Pièces de moulage par injection de métal

-

Parties de moulage par injection de poudre

-

Pièces de métallurgie des poudres

-

Pièces métalliques sintrées

-

Parties d'usinage CNC

-

Parties d'usinage pour le tournage, le fraisage

-

AEG Partie Airsoft accessoires

-

Pièces de boîtes de vitesses pour pistolets airsoft

-

Outil porte-clés extérieur

-

Rameau à joints plats et lave-linge

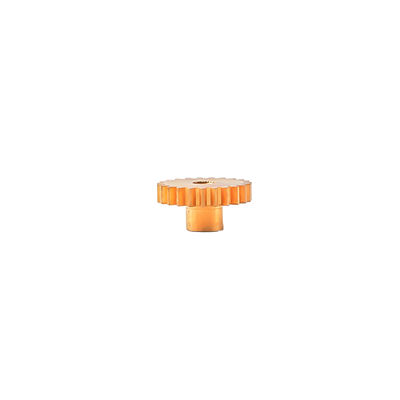

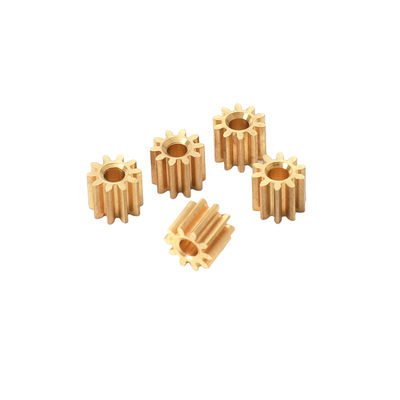

Customized Small Powder Metallurgy Gear with 0.02mm Tolerance and 100% QC Inspection

Contactez-moi pour des aperçus gratuits et des bons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Si vous avez n'importe quel souci, nous fournissons l'aide en ligne de 24 heures.

x| Poids | 0,01 kg | Matériel | Alliage en aluminium |

|---|---|---|---|

| Traitement de surface | Anodisation | Tolérance | 0,02 mm |

| Méthode de traitement | Lathes à usinage CNC | Composition chimique | C, Si, Mn, P |

| Type d'acier inoxydable | 316L, 304L | Forme | personnalisé |

| Rapport de test | Disponible | Inspection vidéo | Fourni |

| Quantité de commande min | 100 | Emballage | Poly sac + boîte intérieure + carton |

| Contrôle de qualité | Inspection de qualité à 100% | Taille | Tailles personnalisées acceptables |

| Couleur | Couleurs personnalisées | ||

| Mettre en évidence | 0.02mm Tolerance Powder Metallurgy Gear,100% QC Inspection Sintered Metal Gear,Customized Brass Copper Gear |

||

| Item | Value |

|---|---|

| Place of Origin | China, Guangdong |

| Brand Name | MDM |

| Model Number | none |

| Application | Industrial, construction, medical, Marine, electronics, furniture |

| Shape | According to client's drawings |

| Material | 316L, 304L, Stainless steel |

| Chemical Composition | C, Si, Mn, P |

| Applicable Industries | Building Material Shops, Machinery Repair Shops |

| Spare Parts Type | Mod spare parts |

| Test Report | Available |

| Key Selling Points | Competitive Price |

| Tolerance | Generally 0.05mm |

| Video outgoing-inspection | Provided |

Dongguan Minda Metal Technology Co., Ltd. was founded in 2015. We specialize in producing MIM parts, PM parts, CNC machining parts and Aluminum alloy, Magnesium alloy and Zinc alloy die casting parts. We also undertake corresponding product mold design, development and production.

Our professional sales staff communicate with customers to understand their needs and convey them to technical staff. The general manager provides quick quotations suitable for each product.

During production, we conduct quality checks at all stages. Products undergo full inspection before shipment to ensure no defective items reach customers.

For hardware accessories solutions, please contact us anytime - we're available 24/7.